Economical Processes for Re-refining Transformer Oil to Prolong Functionality

Economical Processes for Re-refining Transformer Oil to Prolong Functionality

Blog Article

Protect the Setting With Dependable Transformer Oil Recycling Solutions

The importance of transformer oil recycling can not be overemphasized, especially in the context of environmental preservation. The inquiry stays: exactly how can services effectively choose a recycling provider that lines up with their environmental objectives?

Relevance of Transformer Oil Recycling

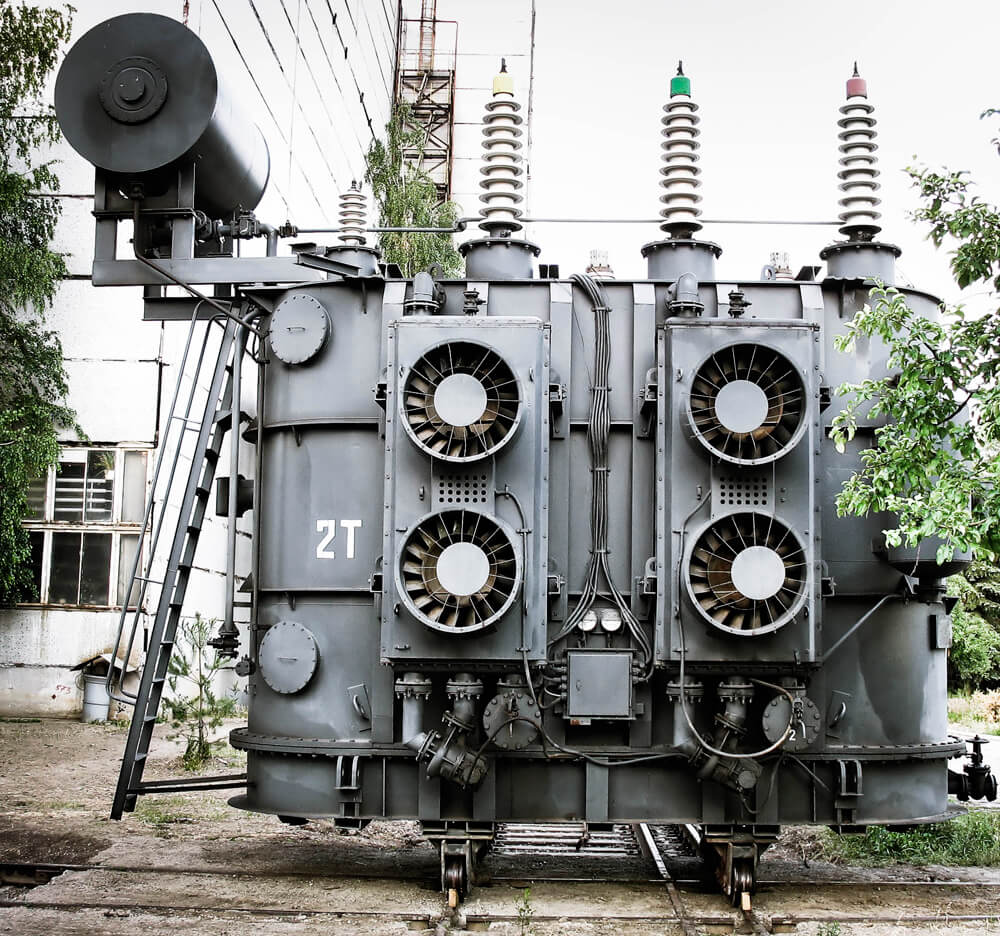

Transformer oil recycling is increasingly identified as a vital practice in the monitoring of electrical infrastructure. The usage of transformer oil, crucial for cooling down and insulating electric transformers, causes the build-up of waste oil that demands responsible handling. Reusing this oil not just preserves beneficial all-natural resources yet additionally plays an essential function in promoting sustainability within the power industry.

Additionally, transformer oil recycling can substantially decrease operational costs for utilities and organizations. By reusing oil, companies can mitigate expenses connected with acquiring brand-new oil and handling waste disposal.

Ecological Effect of Improper Disposal

The inappropriate disposal of transformer oil positions significant ecological dangers that can not be neglected. Transformer oil frequently contains hazardous materials, including polychlorinated biphenyls (PCBs), which can contaminate dirt and water sources if released right into the atmosphere. When poorly thrown out, these hazardous chemicals can seep into groundwater, posing serious wellness threats to neighborhood environments and communities.

Moreover, transformer oil can disrupt water habitats when it goes into bodies of water, leading to destructive effects on fish and various other wild animals. The oil creates a film on the water surface, restricting oxygen exchange and hampering photosynthesis in water plants. The perseverance of these toxins in the atmosphere can lead to bioaccumulation in the food chain, impacting not just wildlife but additionally human wellness via the consumption of polluted fish and water.

Along with chemical contamination, inappropriate disposal can lead to physical threats, such as oil spills, which call for pricey removal efforts. The lasting effects of neglecting proper disposal techniques prolong past ecological destruction, as areas might face economic hardships as a result of decreased natural sources and increased healthcare prices. Transformer Oil Recycling. Addressing these threats is vital for sustainable ecological stewardship

Advantages of Expert Recycling Providers

Efficient monitoring of transformer oil through professional recycling services supplies numerous benefits that expand past simple conformity with environmental laws. One of the key advantages is the reduction of environmental dangers connected with incorrect disposal. By utilizing specialized reusing procedures, firms can decrease the danger of dirt and water contamination, thus safeguarding ecological communities and public wellness.

Additionally, professional recycling solutions add considerably to source preservation. Transformer oil can be fine-tuned and recycled, decreasing the demand for brand-new oil manufacturing. This not just conserves natural resources however additionally lowers power consumption and greenhouse gas discharges associated with oil extraction and refining.

In addition, involving with expert solutions improves operational effectiveness. Companies can improve their waste administration procedures, making certain that transformer oil is dealt with securely and responsibly. This can result in set you back financial savings in waste disposal and possible obligations connected to environmental damage.

The Recycling Process Discussed

Making use of professional reusing solutions not just assists in lowering ecological dangers and preserving resources yet additionally includes a methodical method to the reusing procedure itself - Virgin Transformer Oil. The recycling of transformer oil starts with the collection of utilized oil, which is commonly contaminated with numerous contaminations, including dirt, water, and metallic particles

As soon as collected, the oil goes through a thorough evaluation to establish its problem and the essential treatments required for reliable recycling. Next off, the oil goes Re-refining Transformer Oil through filtering and filtration processes, which may include vacuum cleaner purification, clay treatment, and degasification. These approaches properly eliminate impurities, bring back the oil to a useful state.

After purification, the recycled transformer oil is evaluated to guarantee it satisfies sector requirements and requirements. This step is crucial, as it ensures that the recycled product is effective and safe for reuse in electrical equipment. The recycled oil is packaged and distributed for reapplication, therefore shutting the loop of the recycling process. By utilizing these thorough steps, specialist reusing solutions ensure that transformer oil is reclaimed successfully, minimizing waste and promoting sustainable techniques.

Picking the Right Recycling Service Provider

Selecting the ideal recycling supplier for transformer oil is an important decision that can substantially affect both ecological sustainability and operational performance. When assessing prospective provider, it is necessary to consider their accreditations and conformity with ecological guidelines. A respectable recycler will adhere to local and national requirements, making sure that the recycling procedure minimizes environmental harm.

Furthermore, examine the supplier's experience and competence in taking care of transformer oil. A recognized company with a tested performance history will have the essential technologies and techniques to recycle oil effectively, protecting its quality and lowering waste. Openness in their processes and willingness to share data regarding their recycling end results can additionally suggest a reliable partner.

Analyze the overall value used by the provider, including their solution reliability, consumer assistance, and the potential for partnership in future sustainability campaigns. By thoroughly considering these aspects, companies can select a recycling company that aligns with their ecological objectives while guaranteeing liable and effective administration of transformer oil waste.

Verdict

In final thought, the value of dependable transformer oil recycling solutions can not be overemphasized. Ultimately, the fostering of reliable transformer oil reusing methods plays an essential duty in cultivating a lasting circular economy and securing essential click over here communities.

The usage of transformer oil, essential for cooling down and shielding electric transformers, leads to the buildup of waste oil that demands liable handling.By reusing transformer oil, business can lower their dependence on brand-new oil production, which is frequently resource-intensive and environmentally taxing. By reusing oil, organizations can reduce expenses connected here are the findings with buying brand-new oil and handling waste disposal.Reliable monitoring of transformer oil with professional recycling solutions offers various advantages that prolong beyond plain conformity with environmental guidelines. Transformer oil can be refined and recycled, decreasing the need for brand-new oil manufacturing.

Report this page